Launching Your Dream Product

In-house 3D printing not only turns digital files into physical objects, but it can turn ideas into a viable product.

The genesis of the Eartune Fidelity dates back over a decade. Justin Stack always had trouble getting the best sound quality out of his headphones; he noticed that when pressure was applied to the headphones, the bass and overall sound quality was greatly improved. His headphones had the ability to deliver a better music experience, but they didn’t fit well in his ear, leading to sound leakage.

The solution was a custom fit eartip.

However, custom ear tips were too expensive and a hassle to produce. There was no scalable, easy way to sell them outside of custom one-off orders.

Stack’s dream of a perfect-fit earphone eluded him for years.

That changed when ADV., alongside SPEK Research Inc., co-developed and patented the Self Precision Ear-impression Kit (SPEK) system to create physical ear impressions. These impressions are mailed to ADV., where they are used in a silicone molding process. The molds are then used to create the Eartune Fidelity, which is mailed back to the customer.

Rapid Prototyping Products in Days

Formlabs printers enable true rapid prototyping. Designers and engineers can carry out multiple iterations of design, size, shape, or assembly based on results of real-life testing and analysis, helping you to bring better products to market faster.

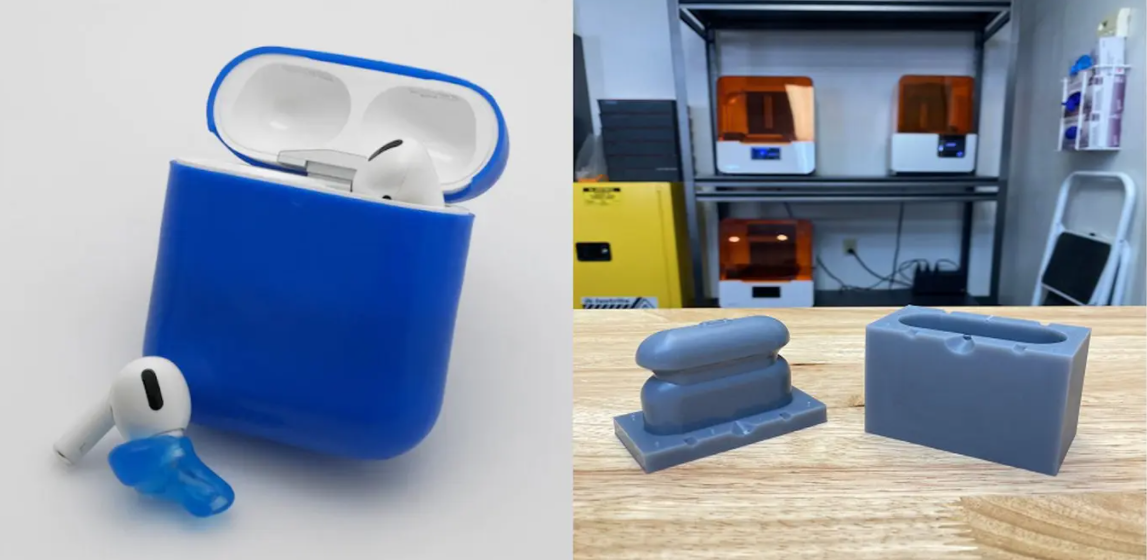

Original feedback on the Eartune Fidelity Kickstarter was positive, except for concerns around a carrying case. Listening to customer feedback, Stack got to work on rapidly prototyping a new case from scratch.

He created a mold design in Meshmixer on a Saturday, and started printing the mold that night. Sunday morning Stack injection molded the part, quickly becoming convinced the case was going to work.

By Sunday night the mold was redesigned and Stack had his first samples in hand on Wednesday. In just five days, the team had created a case that would serve as a companion piece to their custom ear tip. With a few more minor tweaks, the team was ready to ship the cases to customers. In under a week, Stack had created a new product.

Building a Business With Formlabs

Hardware, software, and materials come together in the ultimate package for small businesses looking to bring products to market. From a single engineering tinkering with new design geometries to a team launching a small business, in-house 3D printing is becoming an indispensable tool for product development. Rapid tooling enables you to validate your design and material choice prior to transitioning to mass production, or alternatively provides an affordable means to produce custom or limited series of end-use parts.

ADV. creates molds for injection molding using Grey Pro Resin. Stack told us, “This [resin] gives finished-product surface quality. The Form 3B is definitely better than the older Formlabs printers, in that the surface quality is much smoother right off the print.”

According to Stack, “it’s not just a printer. It’s enabling me to create new products, hire staff, and grow a company. Formlabs gives small businesses access to technology to compete with larger manufacturers that have a lot more capital.”

Stack continued, “without Formlabs products, everything would have cost more, and it would have hampered our ability to scale. In fact, none of this would be possible without Formlabs printers. I’m fulfilling my dreams because Formlabs had their own vision and dream - making an affordable 3D printer - and that’s part of the idea farm that drives American small businesses fo