Spark To go is dedicated to creating a new water bottle system that is both convenient for the consumer and environmentally friendly.

The two co-founders of the Munich-based start up initially came up with the idea of a carbonation system so small that it can fit into a regular water bottle to produce sparkling water on the go.

Developing the idea into a product required prototypes with complex structures, small details, and high strength needed to withstand very high pressures. Equipped with a Form 3 SLA printer, they found a way to build functional prototypes of this complex design idea in a cost and time effective manner.

We spoke to Pieter Prinsloo, one of the founders of Spark To Go, about how he and his co-founder, Luke Patruno, pursue their mission to offer a more sustainable alternative to plastic bottled sparkling water.

Keep reading to learn how Spark To Go utilizes the Form 3 stereolithography (SLA) printer to go from concept to final prototype in just two days, drastically reducing both their timeline and prototyping costs.

Make Bubbles Not Waste

“Consumers in Germany drank more than 10 billion liters of sparkling water in 2020. That is nine times more than what the US drank, with only a third of the population. So Germany really is a special place for sparkling water,” said Prinsloo.

However, the bottled water industry is a large contributor of single use plastics, polluting the environment tremendously. A possible solution in the carbonated water sector: at-home carbonation systems. Designed to turn tap water into sparkling water in seconds, they enjoy growing popularity around the world.

As part of a project on product innovations with a positive impact on the world during his MBA, Patruno came up with the idea of a to-go mini carbonation system. His design proposal required a small carbon dioxide (CO2) cartridge, powered by gas pressure, to be installed inside a bottle, injecting CO2 into the water at a push of a button. This would allow the consumer to have sparkling water on the go for days without re-purchasing single use plastic bottles.

“You can just fill it up with normal tap water, anywhere you are, and then carbonate and have sparkling water that's always fresh and bubbly,” said Patruno.

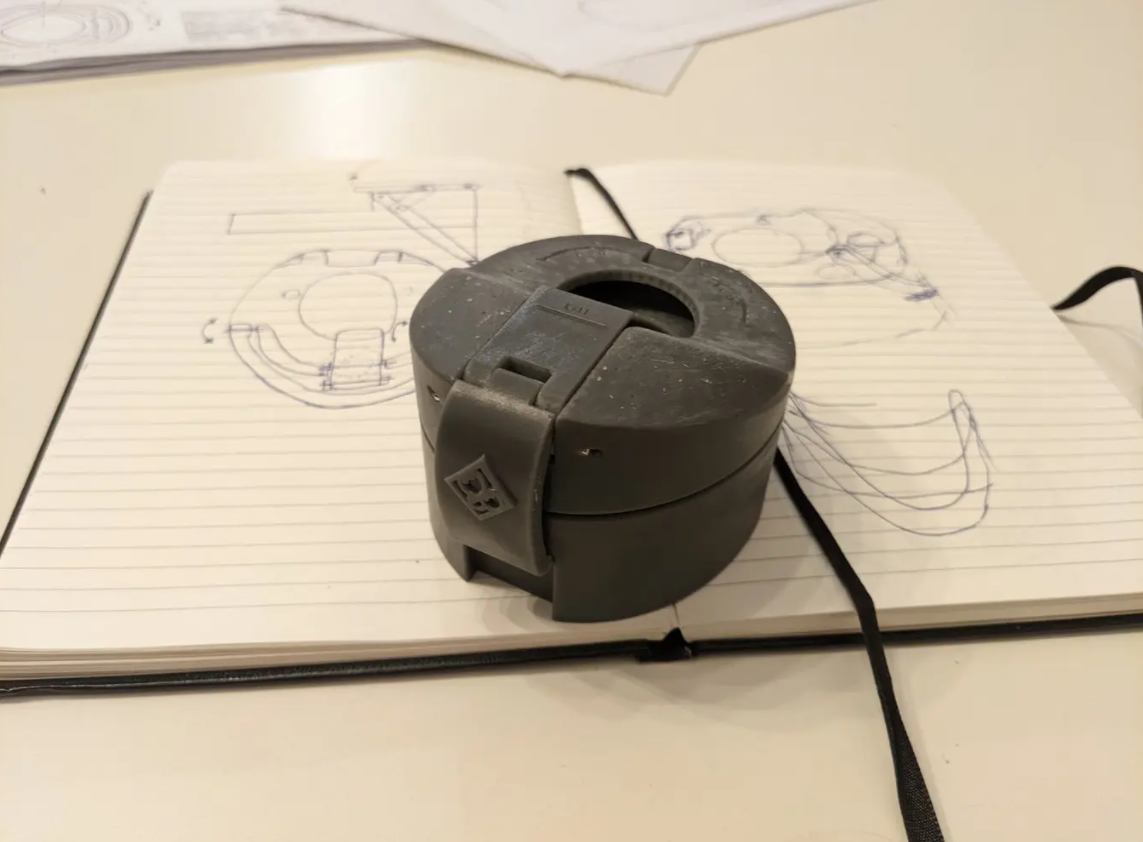

From 2D sketches on paper to one of the initial cap designs, 3D printed using Tough 2000 Resin

Luke and Pieter met in 2019 at an entrepreneurship event hosted by the Technical University of Munich. Brought together by their joint enthusiasm to start their own business and the innovative yet sustainable idea on hand, Spark To Go was founded in 2020, with the goal to produce carbonation systems based on Patruno’s design.

The Spark To Go prototype water bottle with top part printed on the Form 3 in Tough 2000 Resin and painted afterwards

Choosing The Right Technology

To bring their initial idea from a 2D file on their computers to a 3D prototype, Pieter and Luke worked closely together with Formlabs partner Beta2Shape.

The Cap and carbonation mechanism button were prototyped on the Form 3 in Tough 2000 Resin and painted afterwards

In order to meet their specific technical requirements for a prototype of a miniature carbonation system, they compared different 3D printing technologies.

“I was working at Beta2Shape for a short time, which is really where I got a lot of my knowledge in 3D printing and the different technologies. And that is also where I could really firsthand compare FDM with SLA,“ Pieter said.

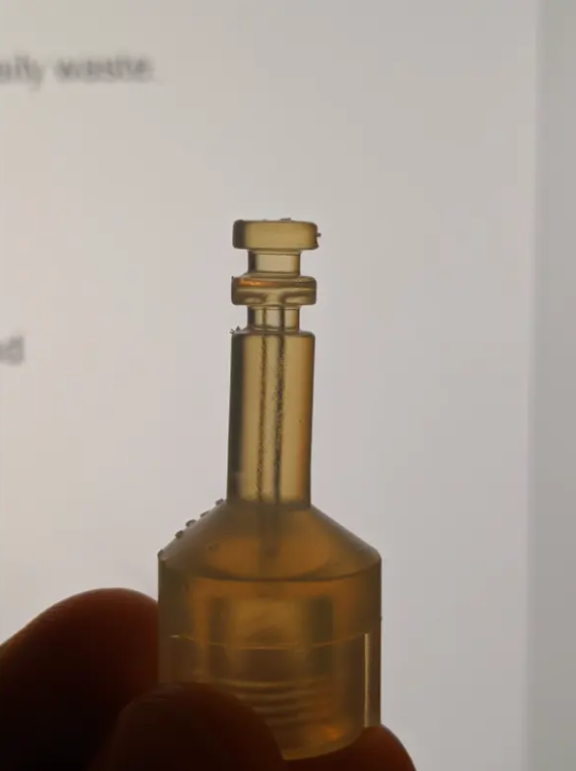

“We needed something that's very strong because in our application, we've got extremely high pressures. It needs to be water and gas tight, and that basically excludes any of the FDM technologies that were out there. We have pressures of around 60 bar inside the small cartridge (60 times atmospheric pressure). When the gas expands, the temperature can drop all the way down to minus 20 degrees Celsius, which was the coldest that we've ever measured on some of these parts. When I saw the engineering range of materials that you guys are offering, that's really what drew us also to the Formlabs series ” Pieter Prinsloo

The young entrepreneurs decided on a Formlabs SLA printer, enabling them to do true rapid prototyping of functional parts and continued to work closely together with Beta2Shape throughout their product development phase. As a small business new to 3D printing, the support and professional advice from Beta2Shape was very helpful to get started. It also enabled them to compare the wide range of resins first hand in their local shop and evaluate them regarding their requirements.

After trying out several resins from the Formlabs material library, Tough 2000 Resin proved itself to be strong enough to withstand both pressure and temperature, while providing the right dimensional stability and accuracy.

Based on their tests with Beta2Shape, the team purchased their first Form 3, and began to develop and iterate their carbonation system and bottle design.

The Form 3 allowed them to produce prototypes in a very short period of time, while having 100% control over adjustments and post-processing details. Using Tough 2000 Resin they printed the mouthpiece and carbonation system of the prototype bottles.

Rapid Prototyping with the Form 3—the Best and Hardest Working Employee

Printing the different iterations of the complex mouthpiece and carbonizing mechanism for the bottle in-house was a major financial advantage for the small start up. Getting the full bottle manufactured from metal was such a large investment, the 3D printed components helped them save money where they could.

“Currently, I'm working on the 14th iteration of the prototype. I checked and we have done upwards of 2,500 hours of 3D printing on this one printer in a little bit more than one and a half years. So it's currently our best and the hardest working employee“Pieter Prinsloo

From 2D to 3D in 24 Hours

To produce functional prototypes ready for showcasing to investors or alpha testing, Pieter and Luke purchased the complete Formlabs ecosystem, featuring the Form Wash and Form Cure.

Print farm set up in the Spark To Go workshop with the Form 3, Form Wash and Form Cure

“[For the systematic top part of the bottle] we had functional prototypes that were 100% 3D printed,“ said Pieter.

Thanks to the post-curing step using the Form Cure, the mechanical properties of Tough 2000 Resin were able to reach their optimal level, meaning it had the tensile strength and modulus to act as a fully functional prototype that can withstand bending, impact, and repeated use.

Time and Cost Savings

“We've managed to scale down [the time to create a prototype] and we can print a complete new set of parts in 12 hours. But then we still have post processing that we need to do. So let's say in two days or 48 hours, we could make a complete new iteration of the prototype,” said Pieter.

The speed of rapid prototyping with the Form 3 is in stark contrast to the traditional methods of outsourcing a prototype to a metal manufacturer. Since they were considering making the Spark To Go bottle entirely out of metal, they tried this out in the beginning of their development journey.

The two decisive reasons why they quickly went back to trusting their Formlabs 3D printer with the job were:

Time: One outsourced prototype of a Spark To Go bottle took up to 8 weeks compared to 48 hours with the Form 3. Crucial time that they can not afford with 14 different designs of the prototype in total.

Money: One outsourced prototype cost them as much as a completely new Form 3 printer.

Moving Towards Production With 3D Printing

Following an alpha test involving six prototype bottles, Spark To Go's next step is to run a crowdfunding campaign before going into production and launching the innovative product on the market.

5 prototypes that were sent out to external users for an alpha test before going into production

Formlabs hardware, materials, and software allow Spark To Go to accelerate their iterative process and cut prototyping costs substantially. These time and cost savings empower them to expand their product line, and innovate new solutions and products contributing to a more sustainable future.

“The reason why we started this company was to really try and provide people with an alternative to bottled water so that when you're out, you don't need to always just buy bottles from the store. And we see this also as a company that could grow into other areas of single use plastics,” Pieter said to state their intentions for the future.

Pieter highlighted that 3D printing has become an essential part of business development at Spark to Go.

“I'm actually going to say that I don't think anything would've been possible without the 3D printer, really. So the big benefit was that we could very easily and also very cost-effectively test many, many different ideas“Pieter Prinsloo