The newly branded Desktop Metal line of printers is derived from the acquisition of ExOne last fall and will soon be offered with Desktop Metal’s build preparation and award-winning sintering simulation software applications. Additionally, the X-Series will now be supported by Desktop Metal’s experienced global support team.

The X-Series line offers a differentiated approach to binder jetting enabled by patented Triple ACT — an advanced compaction technology for dispensing, spreading and compacting powders during the binder jet printing process. This flexible, open material platform architecture is capable of binding together a wide range of powders with a D50 of 3 to 100 microns.

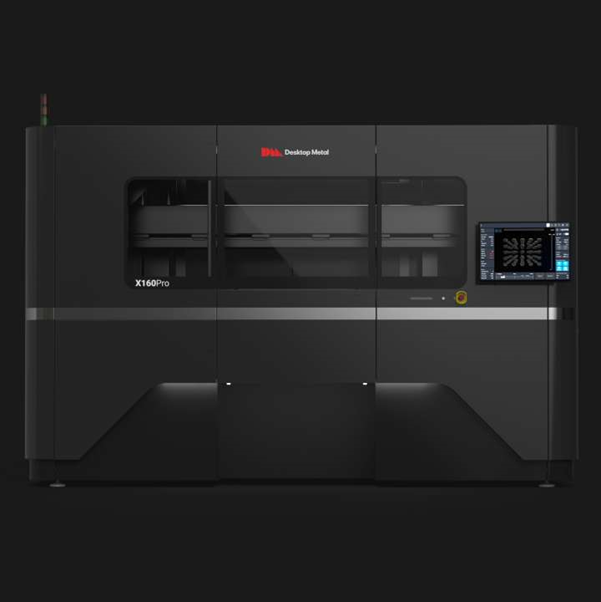

Desktop Metal now offers three X-Series models:

InnoventX™, an affordable, entry-level binder jet system perfect for academic, R&D, and low-volume production applications

X25Pro™, an accessible and productive mid-sized solution already being used for volume production globally, featuring a build box of 400 x 250 x 250 mm

X160Pro™, the world’s largest metal binder jet system, featuring a build box of 800 x 500 x 400 mm

“Desktop Metal’s X-Series printers give customers more choices than ever when it comes to binder jet additive manufacturing,” said Ric Fulop, Desktop Metal Co-founder and CEO. “Our team is moving aggressively to drive additive manufacturing into mass production through a focused strategy of production-capable printers, high-performance materials, and key applications. Binder jetting is the key technology that enables all the benefits additive manufacturing has to offer at scale, from reduced waste to more efficient, lower-risk supply chains.”

For more information, Please visit: https://www.linkedin.com/posts/envisiontec_adaptive3d-xtreme-8k-dlp-activity-6885346056133984256-jzy8