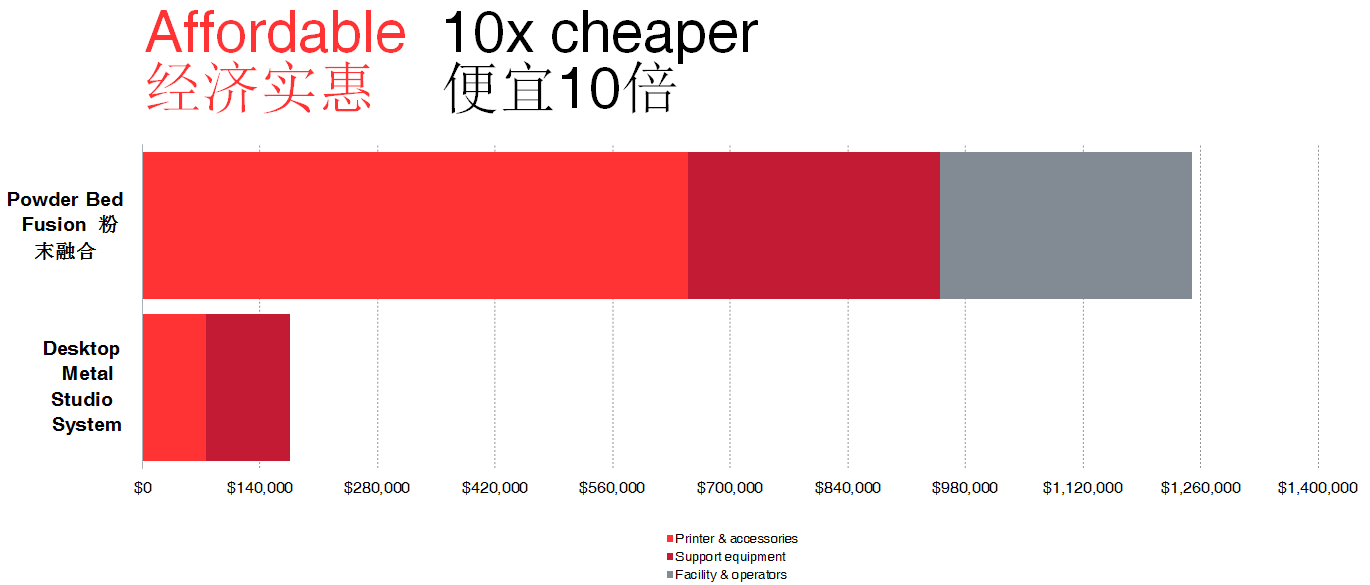

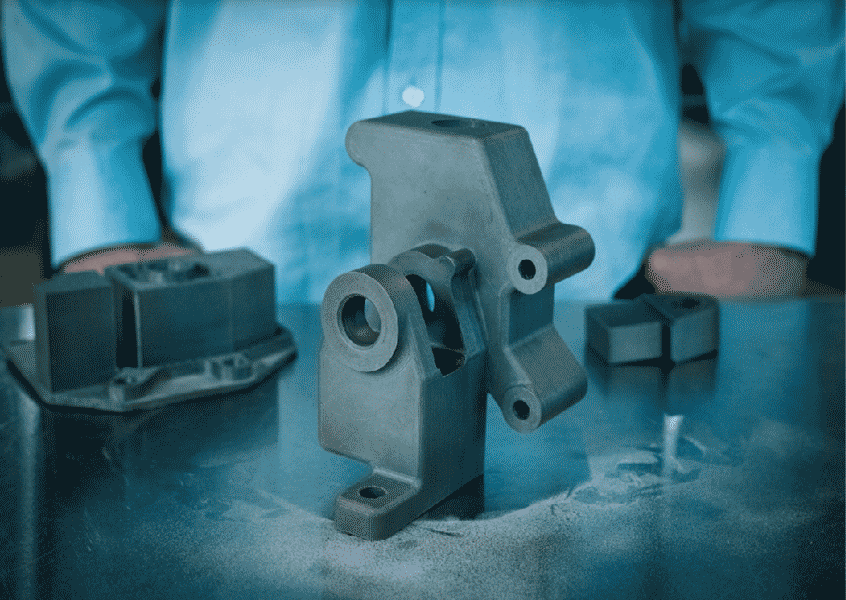

Desktop Metal s DM Studio System is the world s first low-cost, office-friendly metal 3D printing system Safe and simple to use, the DM Studio System is designed to bring metal 3D printing to the design department, allowing engineering and design teams to manufacture metal parts faster without the need for third-party equipment or dedicated operators

Summary

Summary

Advantage

Advantage

Desktop Metal - Studio System Creation

Complete system

· Printer, Debinder, Furnace

· Software that optimizes the entire process

Office friendly

· No need for special facilities or external ventilation

· No hazardous powders or chemicals

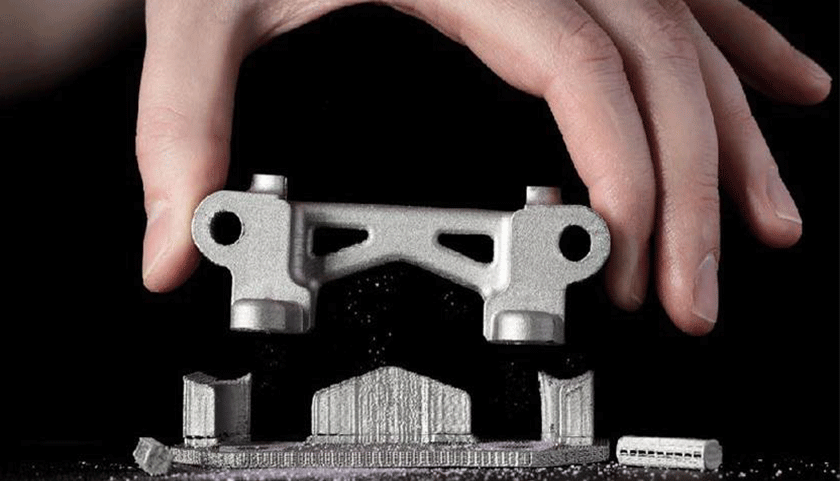

Detachable Support Technology

· Enables printing of large parts and the removal of metal support structures by hand

· Software automatically generates seams to eliminate the equivalent of mold-lock situations

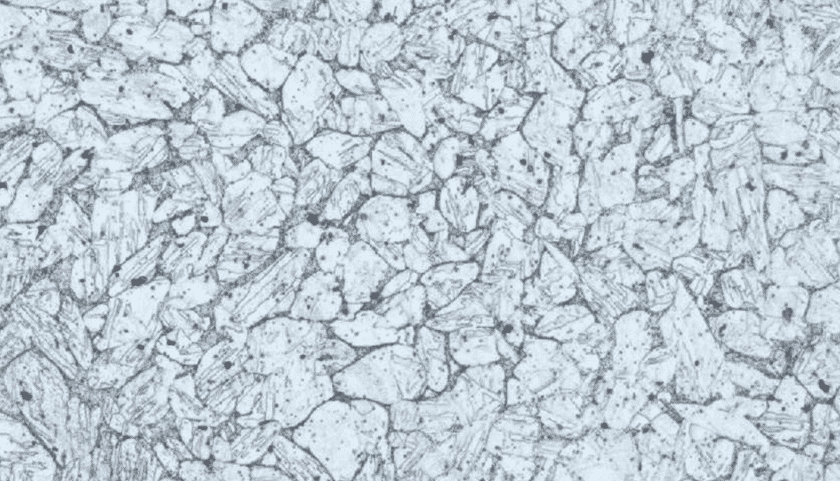

metallurgy

· System and process to support a wide spectrum of metal alloys

· World-class team of materials scientists to drive rapid innovation

Software-controlled workflow Ease of use, office friendly, affordable metal, 3D printing designed for engineers

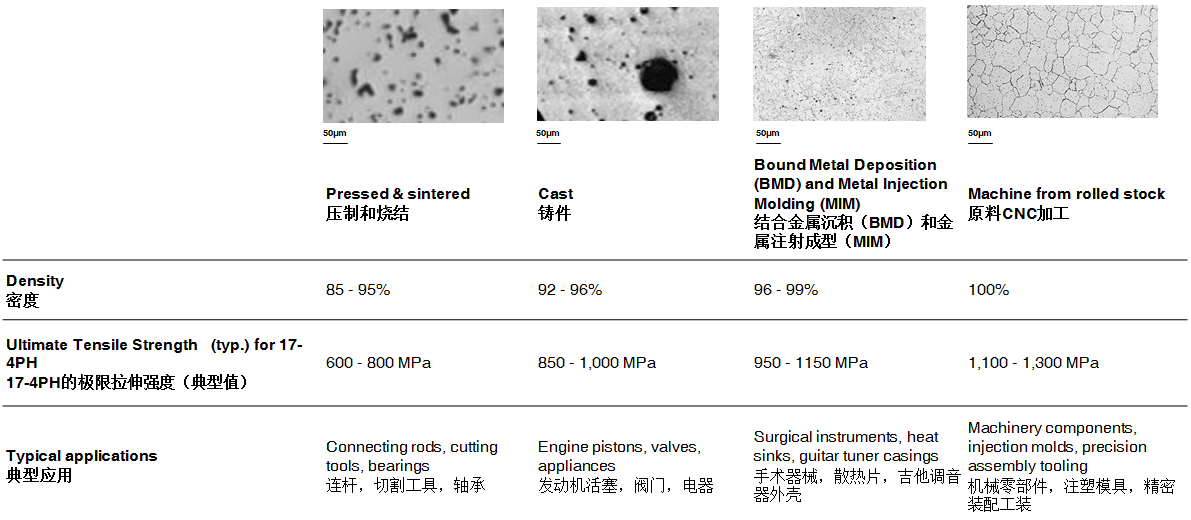

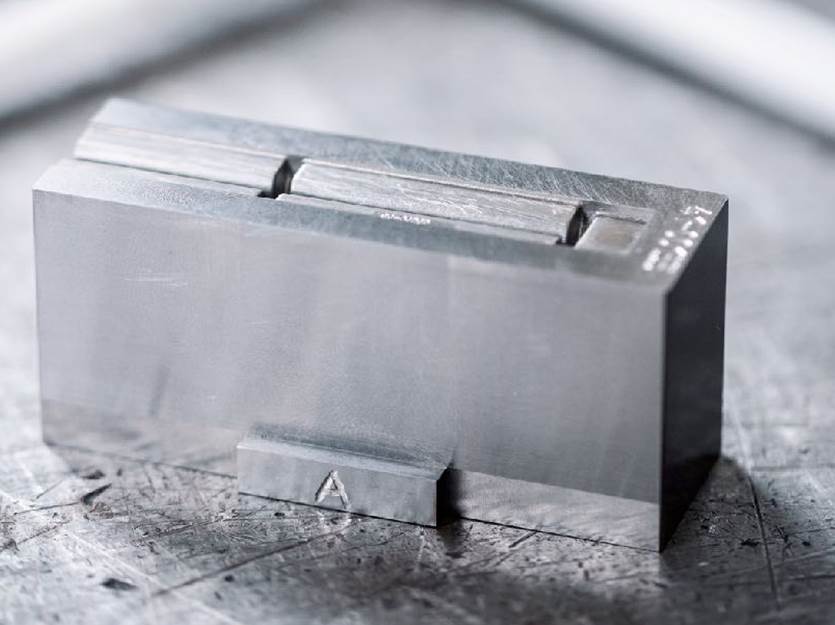

Desktop Metal - material, geometry, finish

Wide range of materials

· (MIM) powder supply chain Designed around the metal injection molding (MIM) powder supply chain

· Seven alloys available

· Over 31 R&D alloys

Produces near net shape parts

Resolution, precision and surface finish similar to casting

· Size capability ±0.5% to ±0.8%

· Critical dimensions can be achieved by post-processing

Build Volume: 12 x 8 x 8 inches

Optimum part size envelope: 5 x 5 x 5 inches and smaller

Material properties close to machined parts

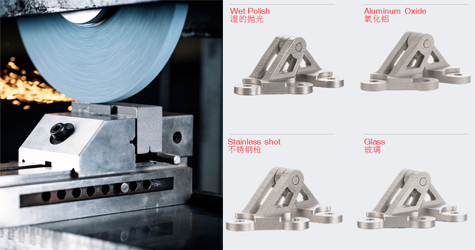

Post processing options

· Post-processing operations (eg, CNC, EDM, grinding, etc.) to achieve critical dimensions and finish

Fully compatible with traditional finishing operations (tumbling, media blasting, electroplating, etc.), welding, heat treatment, etc.

Studio System: 4application cases

functional prototype

The Studio system allows you to iterate quickly. The printed parts meet the thermal and chemical requirements, as well as resolution and precision requirements, required for functional prototyping.

Fixture

The ability to print complex geometries and print-in-place components makes the Studio system an ideal solution for low-volume, fast-rotating jigs and fixtures.

Mold manufacturing and processing

High tooling costs and cycle times make the Studio system a suitable choice for tooling applications where parts have complex geometries such as positive cooling channels.

Low volume production

The Studio system brings the benefits of in-house additive manufacturing, providing rapidly customized parts for low-volume applications.

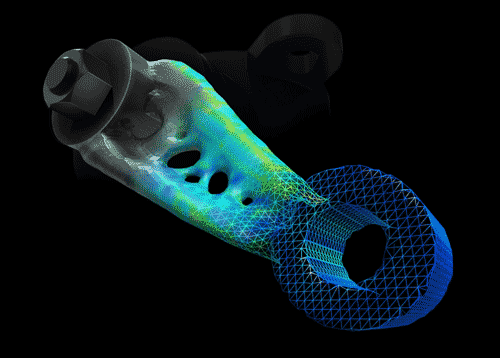

Live Parts

Explore new approaches to generative design. Generate designs in minutes

* Temporarily only available for SOLIDWORKS users

Design

Studio System

Office-friendly, affordable metal 3D printing designed for engineers

* Ships to Pioneers starting in Q4 2017

Prototyping

Production System

100 times faster. Quality and cost per part need to scale. Designed for throughput

* Ships to Pioneers from the first quarter of 2019

Mass Production