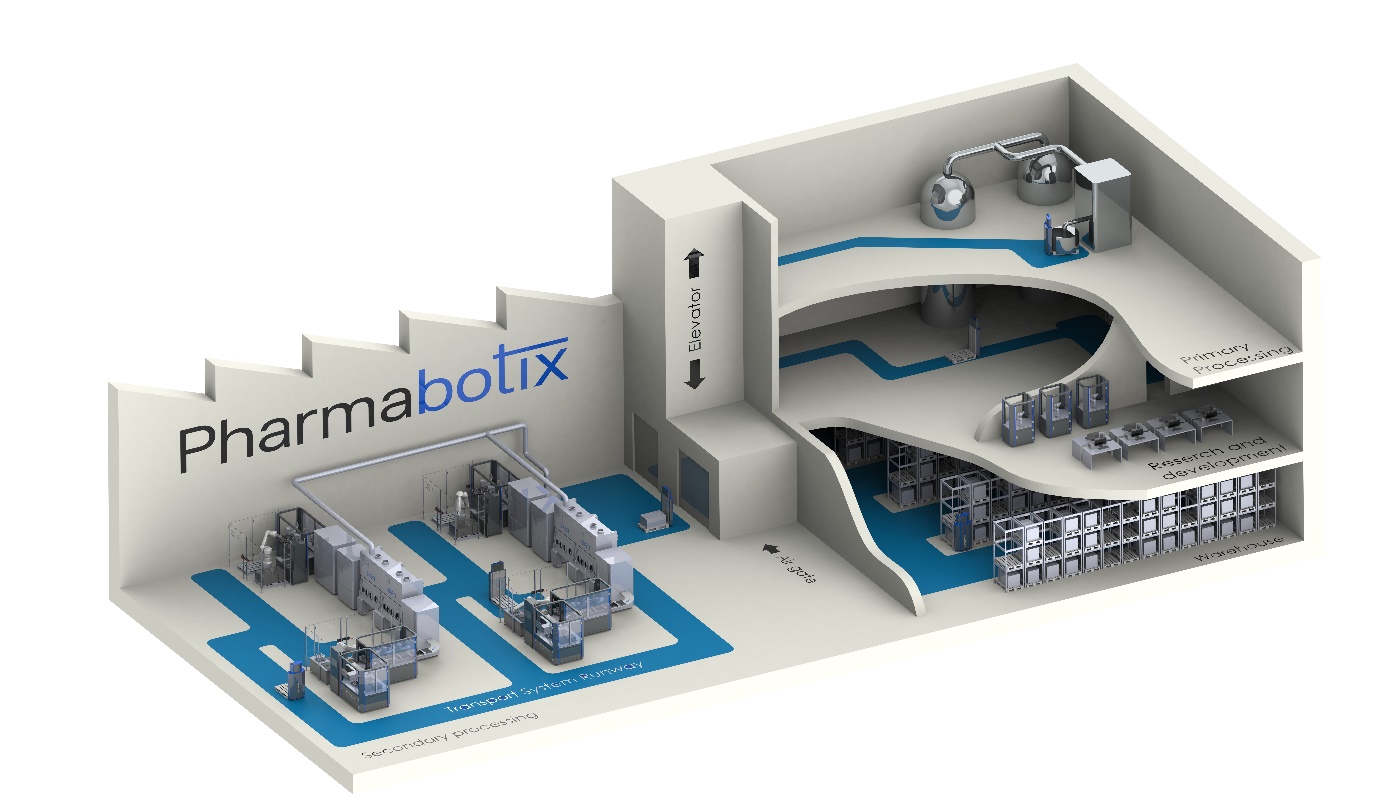

Pharmaceutical companies need to leverage automation and robotics technology to streamline production. Pharmabotix was established to meet this growing demand. The Swiss startup aims to become a leading technology partner in the fields of robotics and automation for the pharmaceutical industry so pharmaceutical companies can bring products to market more quickly and safely, thereby contributing to the well-being and health of society.

When CEO and cofounder Fabian Stutz established Pharmabotix in 2021, he realized that the right design and engineering tools would be critical to ensuring the company’s success. Regulatory requirements in the pharmaceutical industry demand secure, traceable data and document control. Stutz knows he made the right choice in leveraging the power of SOLIDWORKS® for design and the 3DEXPERIENCE® Works portfolio for collaboration, communication, and data management solutions.

Speed Product Development Even in Regulatory Environments

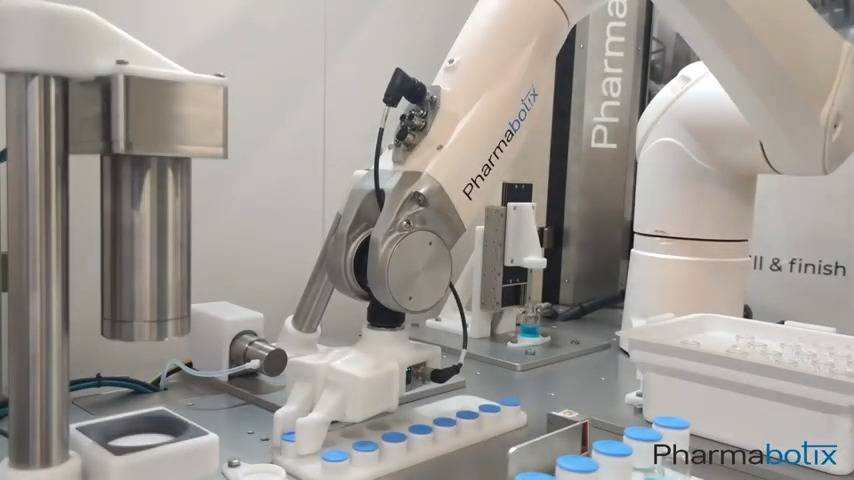

By implementing SOLIDWORKS and 3DEXPERIENCE Works, Pharmabotix has realized a 20 to 30 percent savings in design turnaround time, satisfied regulatory requirements, increased collaboration with customers, and launched its innovative VialPro vial-filling line of products.

“The pharmaceutical industry is subject to a strict obligation to provide evidence of revision and document control on the design of all production facilities used to make and package prescription and over-the-counter drugs,” says Stutz. “With the 3DEXPERIENCE platform, we now have a central, scalable portal in the cloud, where all parts and assemblies, including data sheets, are securely stored and accessible. And the security of our data is assured by two-factor authentication and data encryption.”

Pharmabotix’s initial product development effort involved the VialPro product family, which was specifically designed for liquid vial or solid vial-filling lines, providing a robust end-to-end automation solution to challenges involved in handling primary containers. “We used the 3DEXPERIENCE platform and its applications for the entire development process, as well as for assembling and commissioning new products,” Stutz notes.

Optimized Workflows and Collaboration Equals Better Products

In addition, Pharmabotix values the formalization the 3DEXPERIENCE platform brings to product development workflows and the increased collaboration and communication it facilitates among the development team, resulting in better products. “The predefined workflows allow tasks to be assigned, while project progress can be viewed at any time via the customizable dashboards,” Stutz explains.

The 3DEXPERIENCE platform has also opened up completely new possibilities for collaboration and communication during the Pharmabotix product development process. “Developing products in close collaboration with our customers will help the design and the functionality of our systems stand out from the competition,” says Stutz.

He continues: “With the 3DEXPERIENCE platform, we have a development environment that scales with business growth at a predictable cost. The cloud-based platform does not require any additional IT investment or costs for backups, updates, or other administrative tasks, because they are done automatically on the platform.”