Fibre is a new desktop fiber composite 3D printer launched by 3D printer manufacturer Desktop Metal It uses industrial-grade composite structure 3D printing technology to create high-precision, high-strength and high-stiffness composite parts through continuous fibers

Summary

Summary

Advantage

Advantage

If the video does not play, please allow the browser to run Flash

Fiber Printer Specification

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fiber Printer Applications

|

|

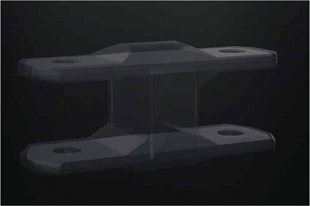

Industrial Manufacturing Fixtures and Fixtures

|

Applications in extremely high temperature environments

|

|

|

|

Alternative to aluminum or steel parts 2 times stronger than steel partsOnly 1/2 the weight of aluminum parts |

Antistatic Nylon 6 + carbon fiber and PEKK polyetherketone ketone + carbon base materialFibers meet antistatic standards Tensile strength > 30 times that of ABS material |

How Fiber Printers Work

|

|

|

| Melt Extrusion Process ——FFF coiled wire printing method |

Microfacet automatic tiling process (µAFP) ——Reinforced continuous fiber belt pressure roller printing |

Mechanical Analysis of Printed Pieces ——Analysis of special software for printing |

Fiber Printer Consumables Library

|

Fiber coiled wire (FFF)

|

PEKK polyetherketoneketone Low cost material Excellent mechanical properties, chemical resistance and surface wear |

|

Continuous fiber tape (µAFP microfacet fiber tiling technology)

|

Carbon Fiber (CF) High strength and stiffness Low cost |