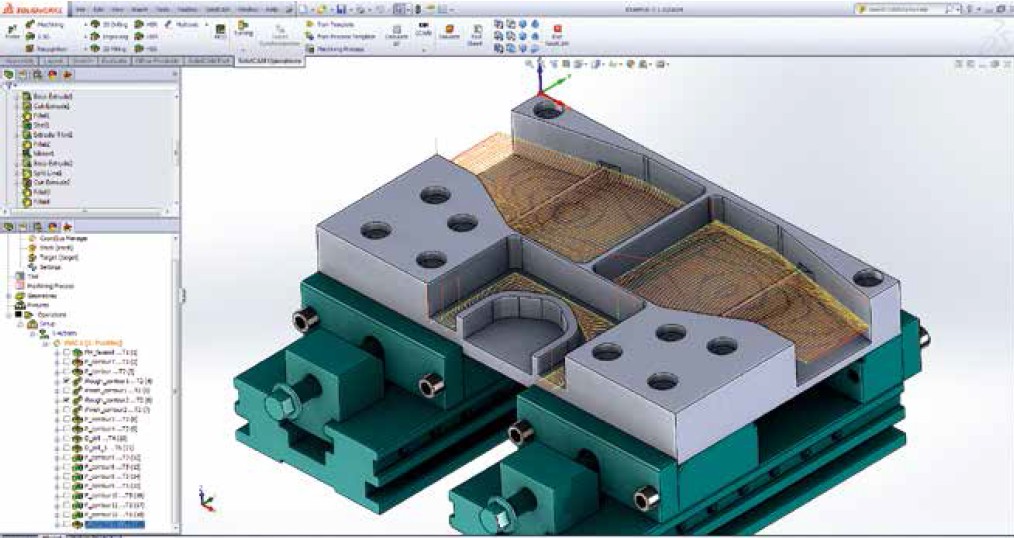

SolidCAM mainly includes iMachining 2D, iMachining 3D, 2 5D milling, high-speed surface milling, 3D high-speed milling, polyhedron machining, five-axis simultaneous machining, turning, advanced turning and milling compound machining, wire cutting and online inspection functions

Summary

Summary

Advantage

Advantage

Product advantages:

1. Powerful, easy to learn and use, complete CAD/CAM solution to support all CAM needs 2. The unique and revolutionary iMachining processing technology saves 70% of the processing time, or even more, and significantly improves the service life of the tool

2. The unique and revolutionary iMachining processing technology saves 70% of the processing time, or even more, and significantly improves the service life of the tool

3. The iMachining process wizard can automatically set the speed, feed rate and other processing parameters, providing a reliable guarantee for processing

4. iMachining can save processing time and improve processing efficiency, and convert it into profit and success rate

5. High level of seamless integration with Solidworks software and Inventor software, allowing CAE programmers to use CAD software to program on existing CNC machines

6. Real associative design model: when the model changes, the relevant toolpaths can be seamlessly updated in real time

7. Minimize file editing

8. Provides the same look, feel, form and function as SolidWorks or Inventor

Benefits of using in SolidWorks:

● SolidCAM and SolidWorks are seamlessly integrated, and CAM programming operations can be completed under the same interface

● It is completely associated with the SolidWorks model. When the model changes, the corresponding tool path will be updated automatically.

● SolidCAM and SolidWorks are golden partners with more than 10 years of cooperation history.

● SolidCAM can define components such as fixtures, tools and vises on SolidWorks assemblies.

● SolidCAM + SolidWorks has some extensible software packages to support all types of CNC machines and applications.

● Seamlessly integrated CAD/CAM solution - SolidWorks+SolidCAM provides a more competitive price advantage.

SolidCAM features:

| functions |

introductions

|

| iMachining 2D | iMachining 2D combines the knowledge and experience of hundreds of experienced CAM and CNC engineers into one, making it easy and simple to use - enjoy iMachining's process wizards & toolpaths |

| iMachining 3D | Leverage proven iMachining 2D & Process Wizard algorithms for roughing and semi-finishing molds, complex 3D parts and 3D cabinet parts |

| 2.5Dmilling | The simplest, easy-to-use operator interface, seamlessly integrated with SolidWorks, incorporates the latest toolpath technology to provide the fastest, most powerful and easiest 2.5D milling toolpath programming. |

| HSS High Speed Surface Milling | SolidCAM HSS is a module specially designed to generate smooth and powerful high-speed finishing toolpaths for a certain part of the surface, including some undercuts. Using this module, you can easily define the surface to be processed without defining the relevant processing range. , which supports both standard and profiled knives |

| Five-axis positioning machining | SolidCAM has very powerful related functions in 4/5-axis positioning processing: just define a machine tool processing origin, and you can set polyhedron processing with one click - SolidCAM optimizes the setting of polyhedral processing coordinate system and improves the programming of polyhedral parts speed. |

| HSM-3D high speed milling | The HSR function provides us with powerful high-speed roughing strategies, including contour roughing, straight roughing, mixed roughing and residual material roughing. HSM finishing improves the quality of the machined surface, reduces the wear of the tool, and makes the tool have a longer service life. |

| Five-axis simultaneous machining | The tool path can be controlled in all directions during the whole process of processing, and the tool path can be checked for collision. At the same time, it also has a very friendly user interface. All types of five-axis machines are supported, including dual-turntable, swing/turntable, dual-swing, gantry-type machines, as well as the most advanced turn-mill machines on the market today. |

| Turning | Provides a comprehensive turning package that generates powerful toolpaths and provides strong technical support for rich turning operations. Suitable for a full range of turning machines, including 2-axis lathes, multi-turret lathes, multi-spindle turning centers and mill-turn machines. |

| Advanced Turning and Milling | It supports CNC machine programming with all the latest functions, provides powerful programming tools, and is easy to learn and use, with very good flexibility and configurability. Easy to program multi-spindle, multi-turret machines |

| online test | New modules for defining the machining origin and testing on the machine |