The Form 3 is a powerful, easy-to-use 3D printing system designer and manufacturer Formlabs has added to its hardware lineup with the new advanced professional LFS 3D printer that delivers scale prototyping and production as your business grows Affordable, industrial-quality 3D printer

Summary

Summary

Advantage

Advantage

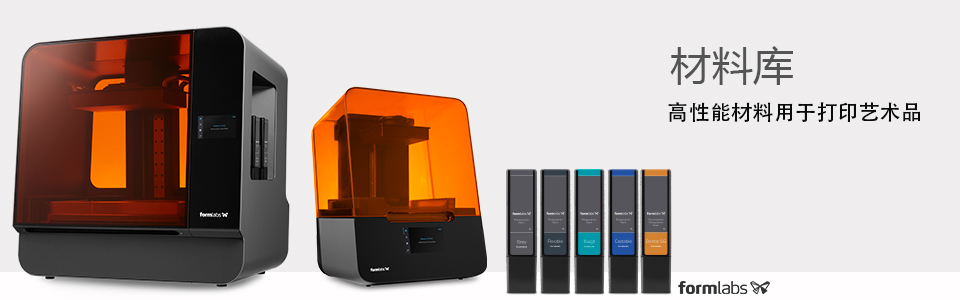

Form 3

A new generation of industrial 3D printers

The Form 3 is a powerful, easy-to-use 3D printing system designer and manufacturer Formlabs has added to its hardware lineup with the new advanced professional LFS 3D printer that delivers scale prototyping and production as your business grows. Affordable, industrial-quality 3D printer.

Form 3features

·Low Force Stereolithography (LFS) technology

Low Force Stereolithography (LFS) 3D printing uses linear lighting and a flexible resin tank to convert liquid resins into flawless prints. This advanced form of stereolithography dramatically reduces peel force, delivering revolutionary print quality and printer reliability.

· Nonstop printing

The form 3 and From 3L constantly monitor print performance so you can focus on bringing your most creative ideas to life, Integrated sensors help maintainideal print condition and send you alerts about the state of your machine.·One platform, 20+ materials

Switch seamlessly between a library of general purpose and specialty resins. Switch between material in seconds with a cross-compatible cartridge system.

·Growth with your business

State with one 3D printer or many, and add capacity as demand grows. Get helpful, human services when you need it from a Formlabs expert.

·Pinpoint precision

The custom-designed Light Processing Unit (LPU)inside the printer uses a compact system pf lenses and mirrors to deliver accurate, repeatable prints. The high-power-desity laser is passed though a spatial filter to guarantee a clean laser spot.

| 規格 | |

| Technology: | Low Force Stereolithography (LFS) |

| Size: | 77.5 × 52 × 73.5 cm |

| Build volume: | 33.5 × 20 × 30 cm |

| Warranty period: | One year (extended period optional) |

| Print resolution | |

| Layer thinkness: | 25 μm (.001 in) |

| Laser spot size(FWHM) | 85μm |

| v | |

| Software compatibility: | Windows 7 and up Mac OSX 10.6.8 and up |

| File type: | .STL or .OBJ |

| Applicable resin materials | |

| Standard resin: | black, white, gray, transparent |

| Engineering resin: | Engineering ash, durable, flexible, high toughness, high temperature resistance, high hardness |

| Color Resin: | 16 colors are optional, any color can be adjusted |

| Dental resin: | Castable resin |

材料概述

| Resin | 100microns | 50microns | 25microns | use | |

| Standard | |||||

| Transparent | √ | √ | √ | · Polished to transparent · Internal plumbing |

· Use light · semi-gloss |

| White | √ | √ | · Opaque agent · Semi-gloss |

· For large, smooth surfaces | |

| Gery | √ | √ | √ | · Opaque agent · Matte |

· Without primer Show details clearly |

| Black | √ | √ | √ | · Opaque agent · Semi-gloss |

· Without primer, Show details clearly |

| Engineering | |||||

| Toughness | √ | √ | · Snap connection · Assembly |

· Rough consumables | |

| Durable | √ | √ | · Trial production of consumer consumables · Packaging Materials |

· Low friction moving parts | |

| Flexible | √ | √ | · Handles, Grips and Overmolds · Cushioning and Damping |

· Wearable Device Consumables · Packaging Materials |

|

| High temperature | √ | √ | √ | · Molding Consumables · Heat resistant fixture |

· Hot air and liquid flow · Environmental testing |

| jewelry | |||||

| Castable | √ | √ | √ | · burn clean · Capture details |

· Designed for investment casting |

| Dentistry | |||||

| Dental SG | √ | · First class biocompatible material | · print surgery and Pilot drill guide |

Form 3 solves complex engineering challenges with a range of functional resin materials

Engineered Grey Resin

Has good stiffness and precision

Grey - Specialty resin with high precision, medium elongation and low creep. This material is ideal for conceptual modeling and functional prototyping, especially for reusable parts.

High hardness resin

Has good stiffness and precision

High hardness resin filled glass, providing very high stiffness and polished surface. This material is highly resistant to deformation and is suitable for thin-walled and characteristic printing.

Durable resin

Lower friction and wear

Durable resins have low modulus, high elongation and high impact strength to produce smooth, shiny parts with high resistance to deformation. This material is mostly used in applications requiring minimal friction.

High temperature resin

High heat resistance

The highest heat distortion temperature (HDT) of the high temperature resin is 289°C @ 0.45MPa. It can be used to print models, do environmental testing or mold casting and thermoforming.

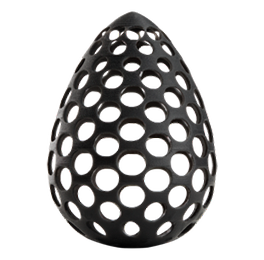

Flexible resin

Suitable for ergonomic design

Use flexible resins to produce curved and compressed parts. The softness is very good to simulate soft-touch materials and add ergonomic features to multi-material components.

High toughness resin

Ideal for making sturdy prototypes

High-toughness resin balances strength and flexibility, making it an ideal material for applications requiring prototype strength and functional assembly parts that can experience brief compressive or tensile forces.

Fast resin

Enables true rapid prototyping

Fast Resin is our fastest print material for fast printing of large parts. With a layer height of 300 microns, it is sufficient for prototyping needs while enabling faster design iterations.

Elastic resin

For soft flexible parts

Elastomeric Resin Our softest engineering resin, this 50A Shore material is suitable for prototype parts typically made of silicone. Choose Elastic Resin for parts that can bend to stretch, compress, and can be recycled without tearing.

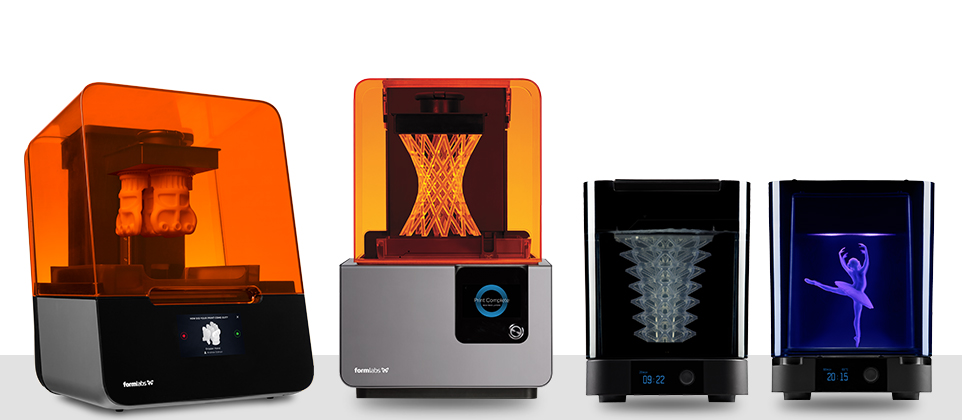

Form Wash + Form Cure

Post-processing tools designed for the Form3 desktop 3D printer

1. Form Wash makes automatic cleaning come true

· Uniform, consistent cleaning

· Designed for building platforms

· Automatic cleaning cycle

· Isopropyl alcohol monitoring

2. Form Cure gives full play to the material properties

Form Cure provides a reliable and professional post-curing solution that can precisely control temperature and light for optimum performance of the cured 3D printed part.