Formlabs first selective laser sintering (SLS) 3D printer, the Fuse 1, uses the same molding principle as the current industrial SLS printers on the market, using laser sintering powder (compatible with nylon PA12 and PA11 powder), but compared to Other SLS 3D printers, the Fuse 1 is much smaller It is reported that the cost of the Fuse 1 3D printer is only one-tenth of the SLS printer, but the performance is better than other SLS 3D printers

Summary

Summary

Advantage

Advantage

Formlabs Fuse 1

Selective Laser Sintering (SLS) 3D Printer

Now, Fuse 1 is kicking off a new wave of indie manufacturing and prototyping. Bring production-ready selective laser sintering (SLS) 3D printing to your desktop.

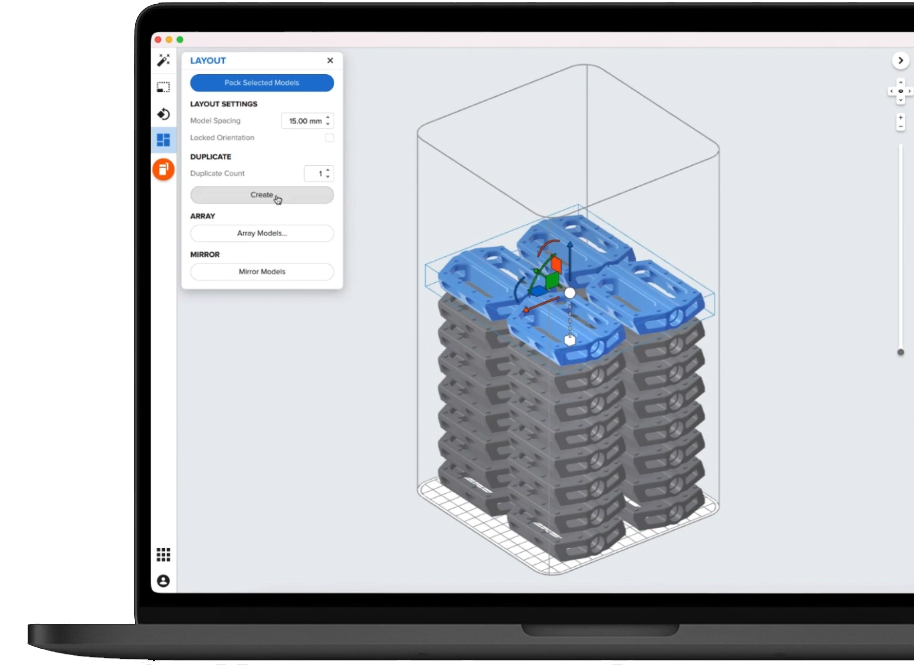

Quick and easy print setup.

Use Formlabs PreForm print preparation software (free to use) to import STL or OBJ part files, orient and arrange models, estimate print times, monitor printers, and upload job files. PreForm's part packing algorithm can automatically arrange many models in a build.

SLS is easy to manage

During setup and printing, the intuitive Touch UI guides you through each step. The touchscreen displays a live stream of the print bed, so you can watch each new layer take shape. You can also get this camera view from your computer's PreForm, so you can monitor printing without leaving your desk. Managed on-demand in-house for production and prototypes, the Formlabs Fuse 1 is capable of delivering industrial power in a small footprint with an effective powder repellant and easy setup features.

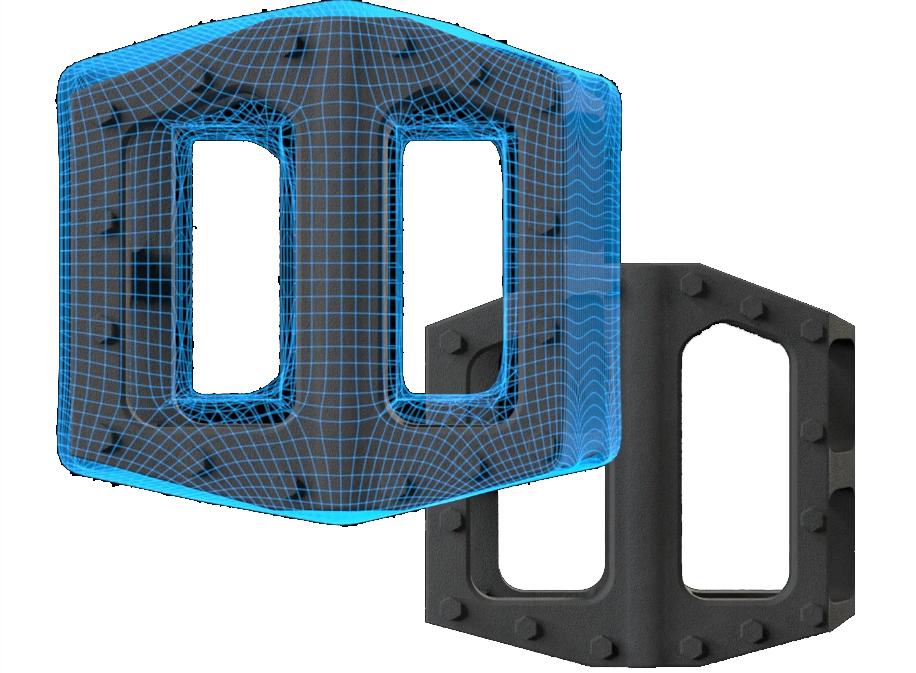

Reliable, consistent printing.

With patent-pending Surface Armor technology, a semi-sintered housing that is printed on the surface of the part, Fuse 1 provides competitive mechanical properties and surface finish without the high cost and hassle of a competitor .

Designed for uninterrupted throughput.

Add a second removable build chamber and additional toner cartridges for continuous printing and less downtime. Industry-leading cooldown time allows you to start printing 1-2 hours after previous prints are complete.

Fuse 1 saves us time and resources from machining or manufacturing parts ourselves. From design to print, we can do it in days, not weeks. The extra time can be devoted to new product development and higher priority, more complex projects, while Fuse 1 takes care of many of the non-functional tasks that our job requires. We try to use it every day as much as possible.

Aaron Noyes, Prototype Machinist, Hypertherm

-

Visible

The Fuse 1 is designed to minimize maintenance time. The full-color touchscreen interface guides you through every step of printing and maintenance. -

Low cost

With reduced equipment costs, affordable materials, and efficient powder recycling, the Fuse 1 is the smart choice for industrial-grade SLS 3D printing. -

Efficient

From print setup to powder recovery, our easy-to-use hardware and software are designed to maximize your efficiency at every step of the process.

Technical Specifications

| Fuse 1 | |

| Technoloty: | Selective Laser Sintering (SLS) |

| Build Volume: | 165 x 165 x 320 mm |

| Print Speed: | 10 mm / hour |

| Layer Thickness: | 100 µm |

| Material Refresh Rate : | up to 50% |

| Startup Time: | 60 mins |

| Internet Connection: | Internet or Wi-Fi |

| Size: | 677 x 668 x 1059 mm |

| Weight: | 88KG |

| Power Requirements: | 2 kW, 120 or 240 VAC |

| Optical System | |

| Ammeter: | Formlabs customization |

| Scanning speed: | 2,000 mm/s |

| Laser Type: | Fiber lasers, rated time >10,000 hours |

| Laser wavelength: | 1064 nm |

| Laser power: | 10 W |

| Laser Spot Size: | 200 µm (FWHM) |

| Software | |

| Preparation for printing: | PreForm Software |

| file Type: | .STL or .OBJ |